CoilCare®

CoilCare® UVGI Surface Disinfection

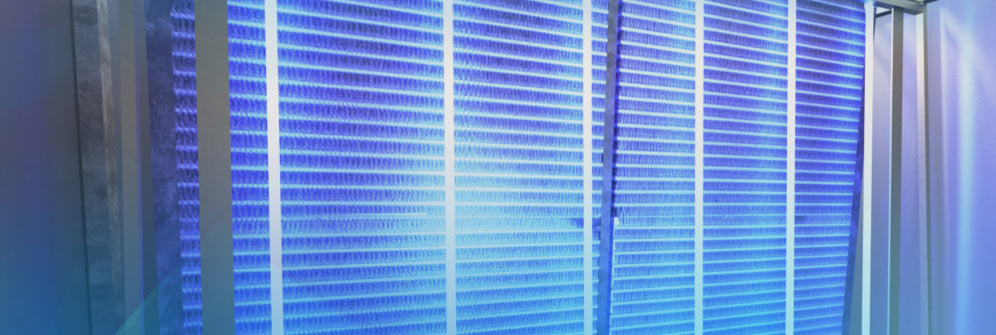

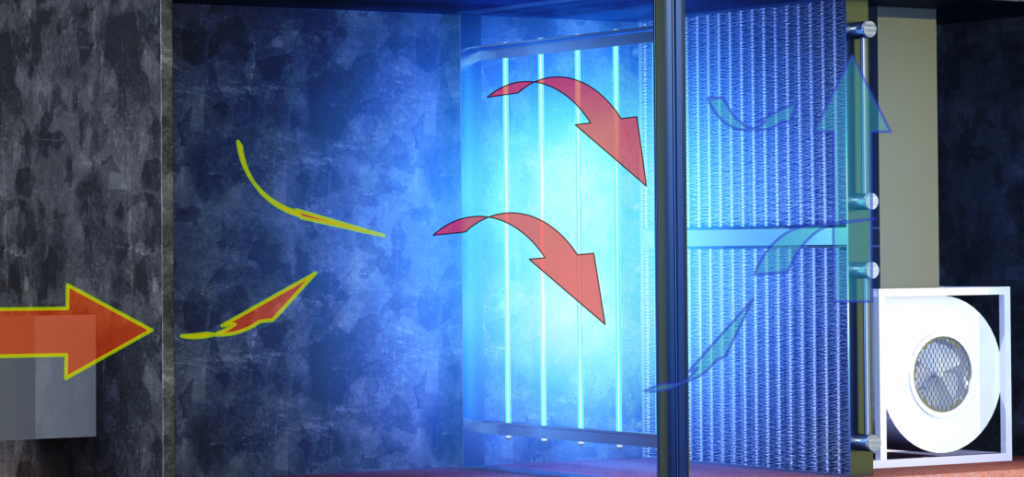

In partnership with BioZone Scientific International we model, supply and install their CoilCare® ultraviolet germicidal irradiation (UVGI) surface disinfection systems using standard or high-output UVC photonisers. Irradiation efficiency is maximised with photon concentrators. The application of UVGI in close proximity to the cooling coil and drain pan within the AHU of an HVAC system eradicates existing biofilm and prevents new biofilm building up. CoilCare® can be fitted to new or existing AHUs in a matter of hours and the ducting system is also cleaner as a direct result of the UVGI disinfecting the airstream.

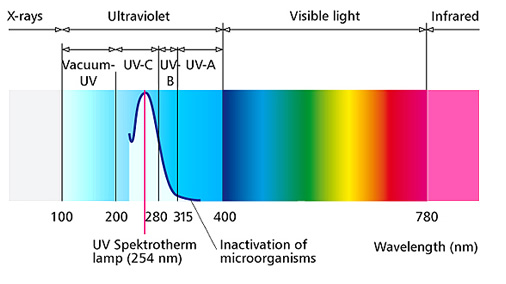

What is ultraviolet germicidal irradiation (UVGI)?

UVGI is the application of ultraviolet C band light (UVC), short‐wave electromagnetic radiation beyond the visible spectrum, at a wavelength of 254 nanometres. As early as 1903, UVGI helped control the spread of tuberculosis. When bacteria, mould, viruses and other organic contaminants are exposed to UVGI the DNA within their cells is disrupted, preventing cell reproduction and resulting in cell death after sufficient exposure. This exposure is calculated at the modelling stage. We provide detailed expected kill rates to accompany CoilCare® AHU sizing specifications.

What is biofilm?

Biofilm is a sticky mixture of dust, microbes, mould and other contaminants that forms in a moist environment such as an AHU. Biofilm reduces the efficiency of the AHU’s cooling coil by restricting thermal conductivity within, and airflow through, the coil. As a direct result there is a measurable pressure drop that can be used to estimate the reduction in system efficiency, along with other factors including:

- Fans and chillers use more energy to achieve the set point temperature

- Energy consumption increases in proportion to the thickness of the biofilm

- A 300 micron biofilm results in over 10% increase in energy usage

- Coils can become so clogged that pressure is halved

Dirty coils can increase the energy consumed by the HVAC system by up to 30%.

Benefits of CoilCare®

CoilCare® returns the performance of an AHU to as built, excepting normal wear and tear, and the efficiency of the HVAC system as a whole is improved. We believe that UVGI is an essential and integral part of any HVAC system. We view it as a ‘just fit it’ technology because of the following benefits:

- Easy mounting system for fast installation into new and existing HVAC systems

- Average payback of 24 months, with energy savings of up to 25%

- Savings from the elimination of manual cleaning and ability to

recycle condensate as grey water - Low initial installed cost, a fraction of the cost of an HVAC system

- Removal of over 99% of microbial contaminants growing on HVAC surfaces

- Eradicates all biofilm on the surfaces of the cooling coil and drain pan

- Airstream passing through the ductwork is free of bio-contamination

and ducting becomes cleaner - Improvements in indoor air quality

- 2012 ASHRAE Handbook compliant

- Opportunity to gain points under BREEAM and LEED

Indoor air quality

A CoilCare® installation provides conditioned air to building occupants. The air is mostly free of bacteria, viruses and other microbial contamination that would usually be transferred into the airstream passing over a cooling coil not disinfected with UVGI.

Reducing the spread of airborne bacteria, mould and viruses lowers the risk of infectious diseases and absenteeism. This directly impacts on the health, wellbeing and productivity of building occupants as it reduces allergic reactions that result in asthma episodes, eye problems etc.

CoilCare® applications

UVGI technology is used to disinfect the surfaces of HVAC systems, ceilings, ductwork, walls, floors and water in:

- Aquariums

- Food processing

- Hospitals and healthcare facilities

- Hospitality venues including hotels and restaurants

- Marine facilities

- Educational buildings including schools and universities

- Swimming pools

- Water treatment plants

A typical CoilCare® system

- Single-ended fixture to carry ballast and UVC photoniser

- Photon concentrators to reflect UVC light for maximum efficiency

- Electronic ballasts: 100-277VAC, 50/60Hz, 0-80°C with lifetime warranty

- The above components comprise a CoilCare® unit

- Single-ended standard or high-output UVC photoniser

- Waterproof photoniser boots

- The above is a CoilCare® unit with UVC photoniser

- CoilCare® units can be mounted horizontally or vertically

- Stainless steel bespoke framework to carry the CoilCare® units

- One or more CoilCare® units is a UVGI array

- Wiring loom from CoilCare® units to wiring box.

- IPC 65 wiring box

- Door interlock switch to turn off the array when AHU door is opened

- UVC safety signage and equipment as necessary

- Porthole to inspect the UVGI array without entering the plenum

- CoilCare® cleaning kit

- The above comprise a CoilCare® system